11. July 2025

This post concludes the mini-series on renovation with Ultra High Performance Concrete (UHPC) and discusses the advantages and challenges of using walls and stiffeners as tools to support the balconies.

For a general introduction to renovation for potential new readers, please refer to the first post in the series on glued connections.

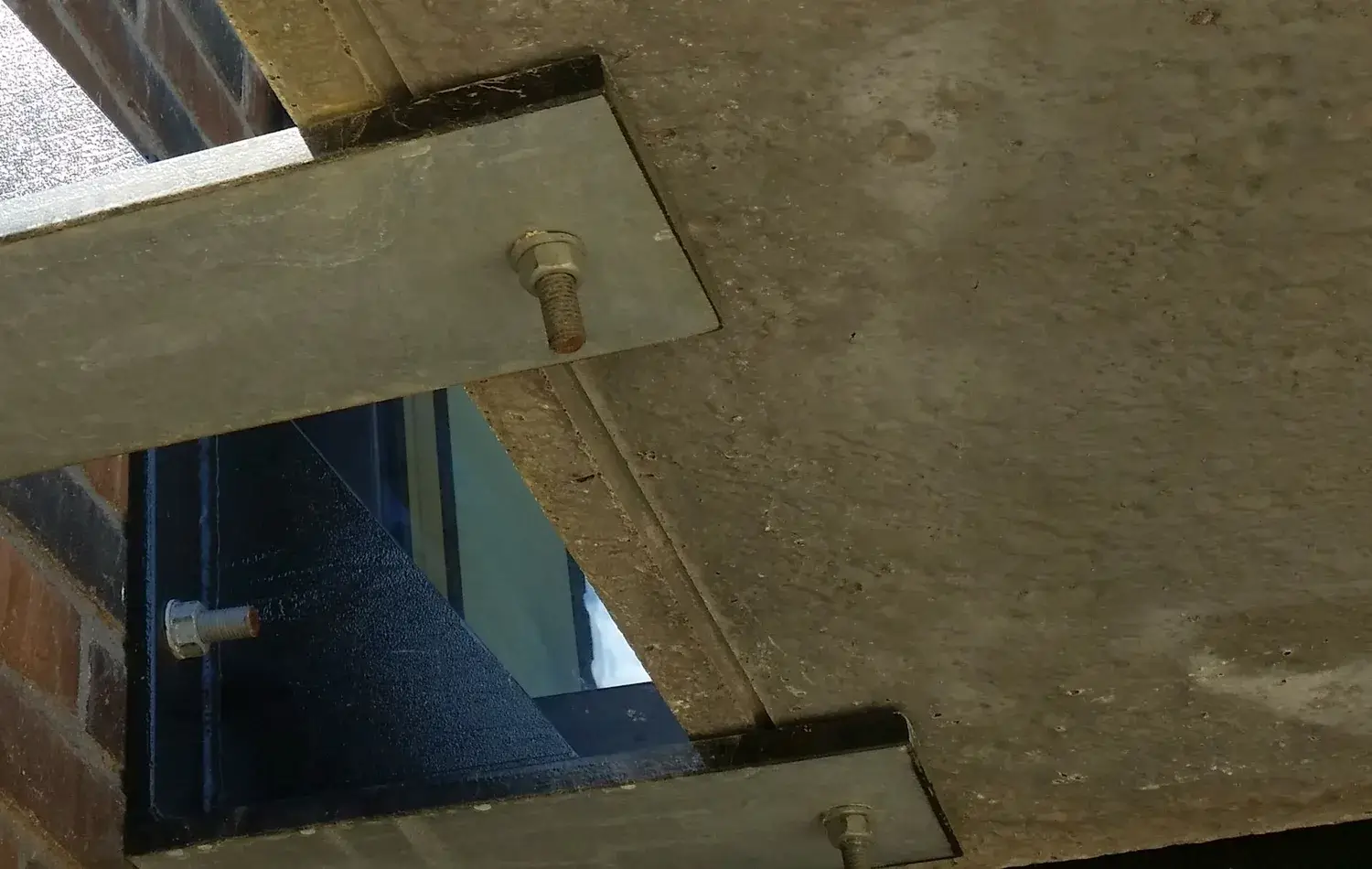

Finlandsparken during the ongoing installation of new balconies. Note the very small dimensions of both the walls and balcony slabs.

Installation is simple with the placement of the balcony on four or five support brackets, depending on the size.

The walls, functioning as cantilevered beams, can be replaced by stiffeners. While this does not add the same rigidity, it still creates an effective load-bearing system.

To provide privacy, light screens are typically added at the location of the stiffeners, as shown in the example below.

To summarize, integrated walls are a good solution when privacy screens are needed anyway because they also make the connection to the building effective when used structurally, and in this case, the low weight and high strength of UHPC is an advantage when supporting the balconies on a per-floor basis.

Distance to the edge: 30-40 mm and slab thickness down to 60 mm are not covered by standard tables from manufacturers of mechanical and chemical anchors and require specific testing and documentation.

THANK YOU FOR YOUR INTEREST!

This concludes the mini-series on renovation with UHPC, outlining some different principles for utilizing the properties of UHPC and the potential advantages and challenges when doing so.

We hope it has been of interest!

The presented examples of solutions are just a small selection of what we could have chosen - we have many other examples, and other solutions will also be developed and used over time.

Are you interested in learning how Ultra High Performance Concrete can be used in your project?

FILL OUT THE FORM AND WE WILL CONTACT YOU